PROJECTS

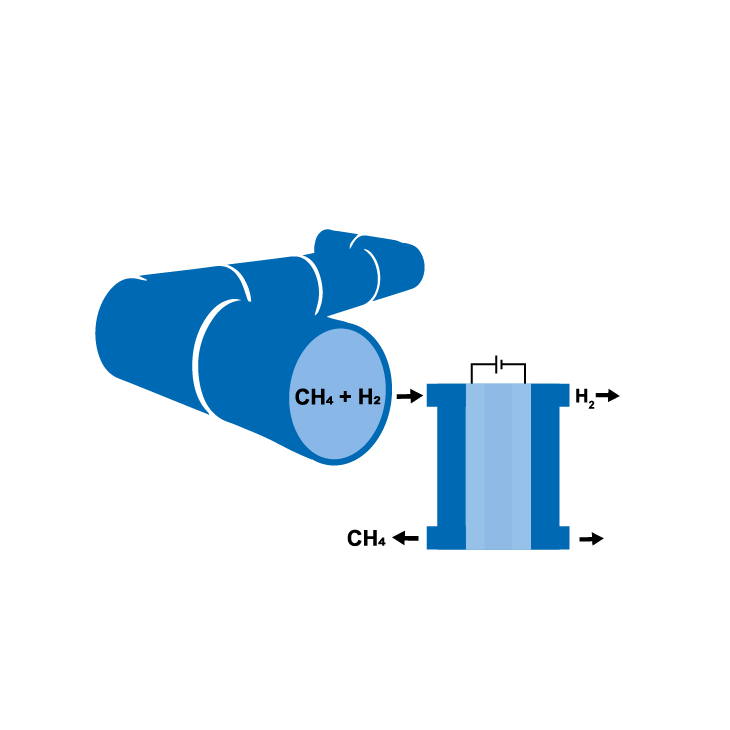

HyInnoSep

Separation modules purify variable hydrogen/natural gas mixtures

Approach

- Anode catalyst development to avoid poisoning

- Module design and testing under industrial conditions

- Dynamic operation and cleaning steps

- Modell-based process analysis, optimization and LCA

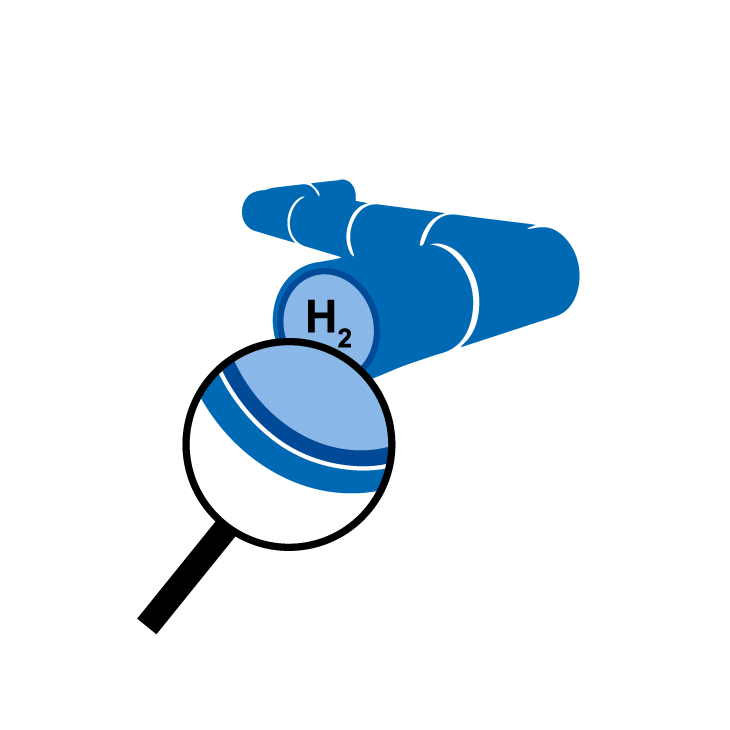

HyInnoNets

Enabling transmission networks for H2 operation

Approach

- Fiber-reinforced plastics (FRP) pipelines:

- Material development & process parameters

- Hydrogen permeation barrier coating by EHLA:

- Development of necessary optics & process development

- Coating of FRP pipelines

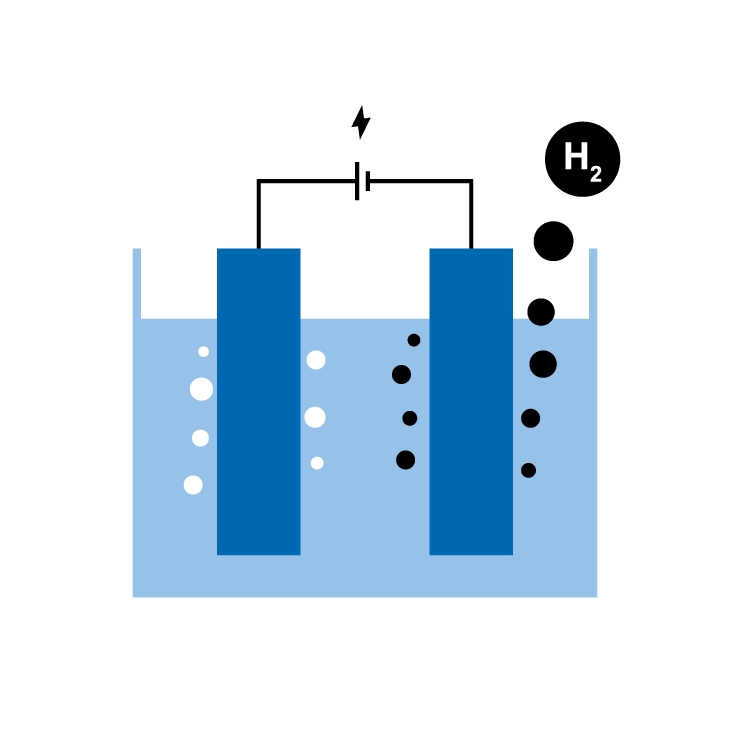

HyInnoLyze

Dynamics, coupled systems and H2 storage

Approach

- Modelling PEMEL & intermediate H2 storage systems

- Analysis of interconnection variations of PEMEL systems, intermediate storages, and power electronics

- Analysis of dynamic behavior in coupled systems and components

- Corrosion and stability tests

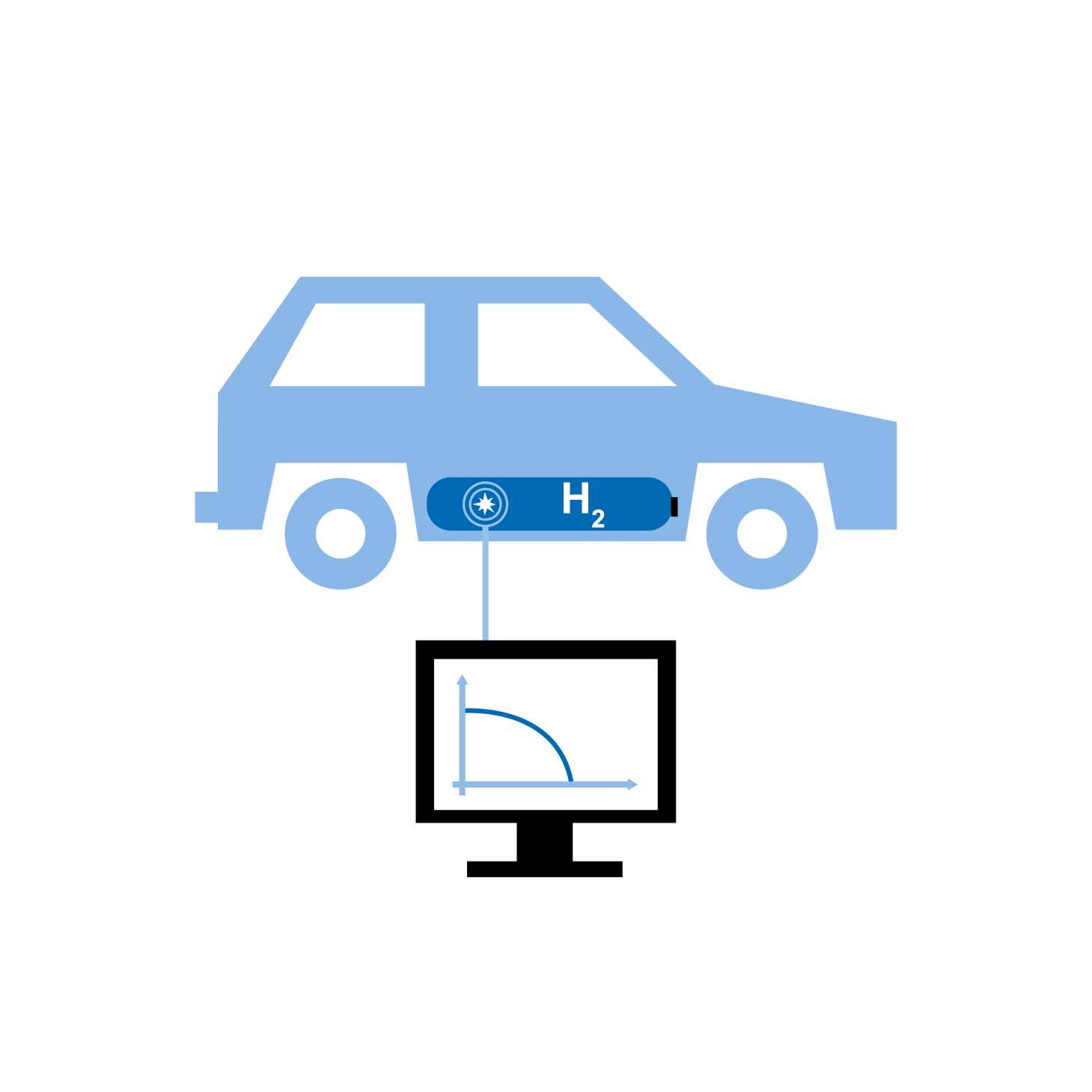

HyInnoTank

Low-maintenance, mobile high pressure tanks

Approach

- Sensor choice and integration

- Sensor testing

- Analysis on pre-damaged tanks

- Investigation of burst pressures and failure characteristics

- Validation of the methods

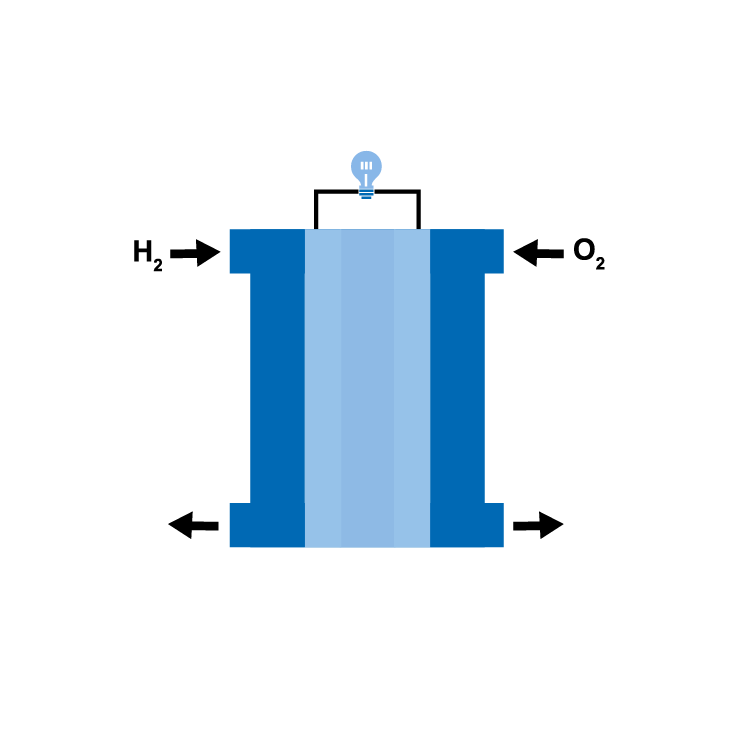

HyInnoPEM

Innovative control, Extended lifetime

Approach

- Test bench construction & identification measurements

- Fuel Cell system & degradation model development

- Development & validation of a model predictive control

- SoH prediction and TCO analysis

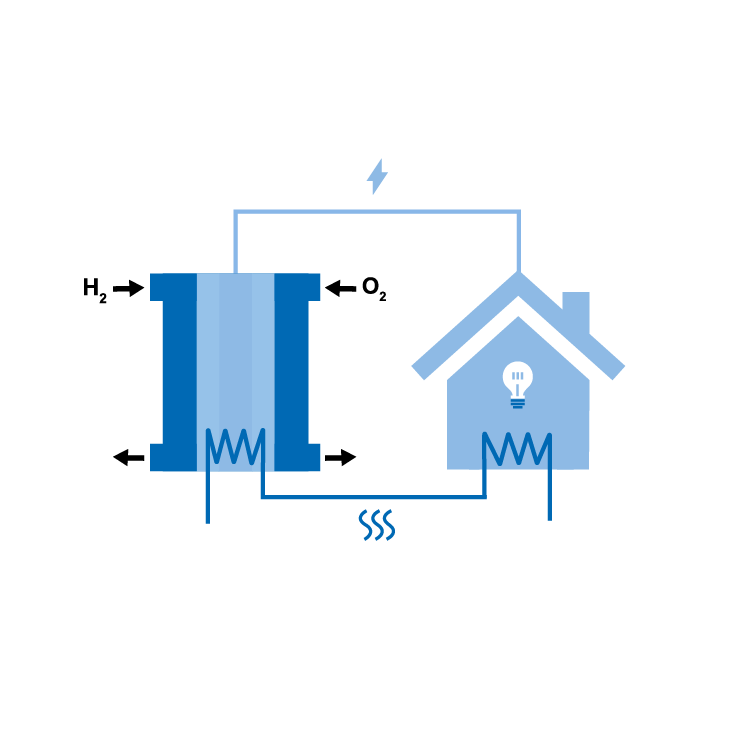

HyInnoSOFC

High-temperature fuel cells with flexible fuel utilization for self-sufficient energy supply

Approach

- Analysis of application cases and delivery scenarios

- Fuel processor system for variable gas composition

- Operating and control concepts

- Determination of the gas composition

- System tests

- Market studies

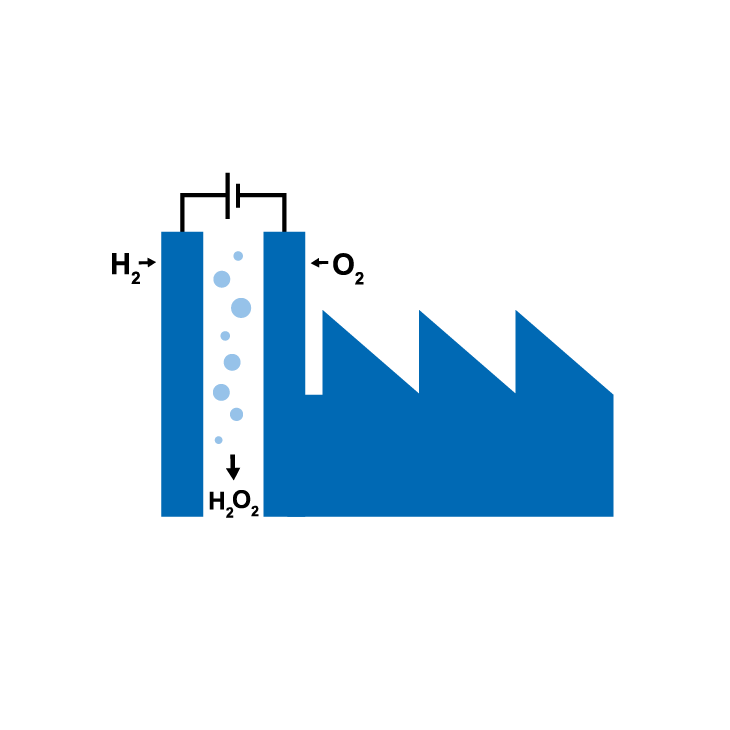

HyInnoChem

Hydrogen peroxide and methanol synthesis using green hydrogen

Approach

- Multifunctional catalysts for adaptable synthesis

- Electrode, membrane and reactor development for highly concentrated and pure H2O2

- Model-based optimization of dynamic operation & LCA

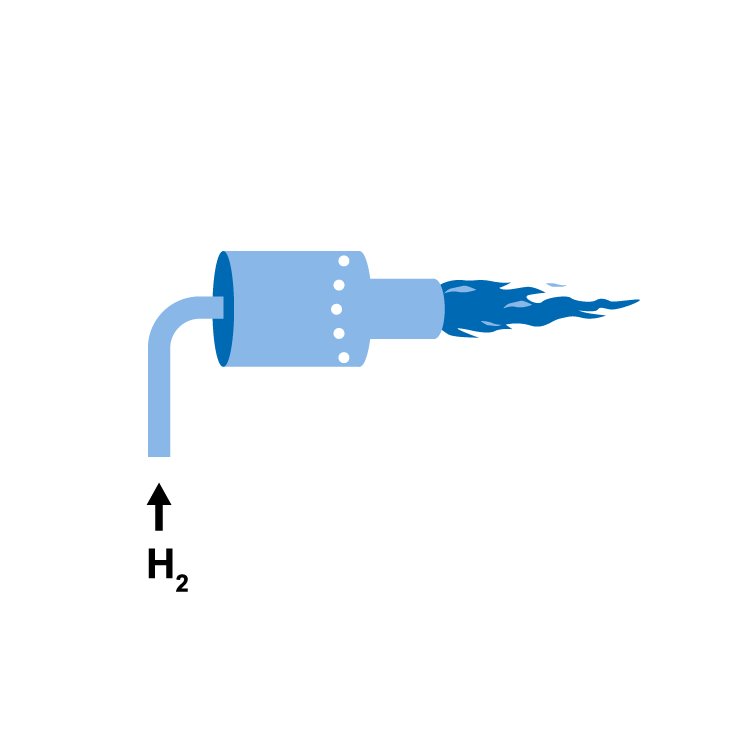

HyInnoBurn

Industrial gas burner development for natural gas-hydrogen mixtures

Approach

- Experimental characterization of hydrogen flames

- CFD simulations

- Algorithmic topology optimization

- Production by additive manufacturing

HyInnoICE

Demonstrator vehicle with a highly Innovative H2 combustion engine

Approach

- Fundamental research on the combustion processes

- Functional development and calibration

- Vehicle integration and testing

- Study of novel fuel systems

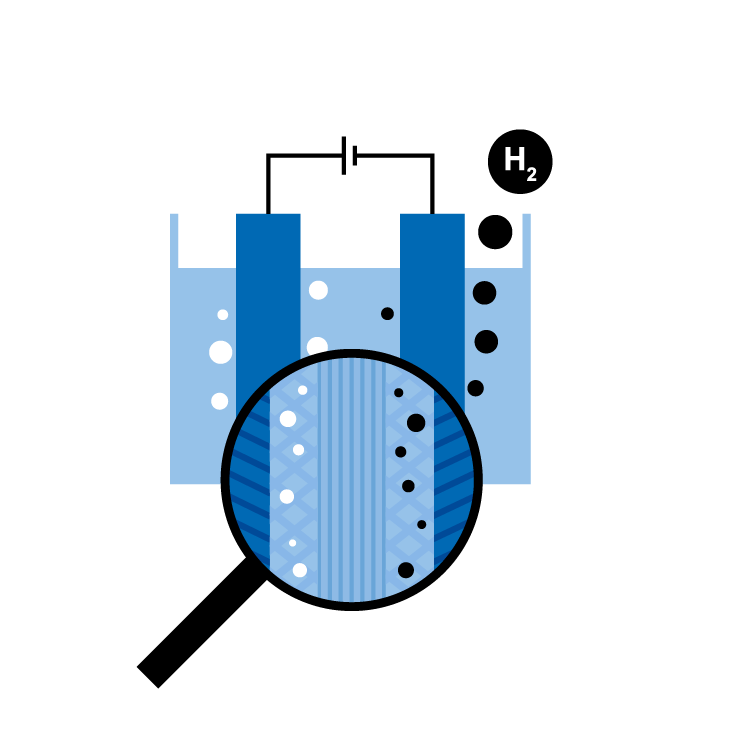

HyInnoCells

Production of electrochemical cells

Approach

- Additive layer manufacturing using expanded metal grids

- Non-noble metal, inexpensive coatings

- Electrochemical testing

- Analysis of the potential for serial production and transfer to fuel cells

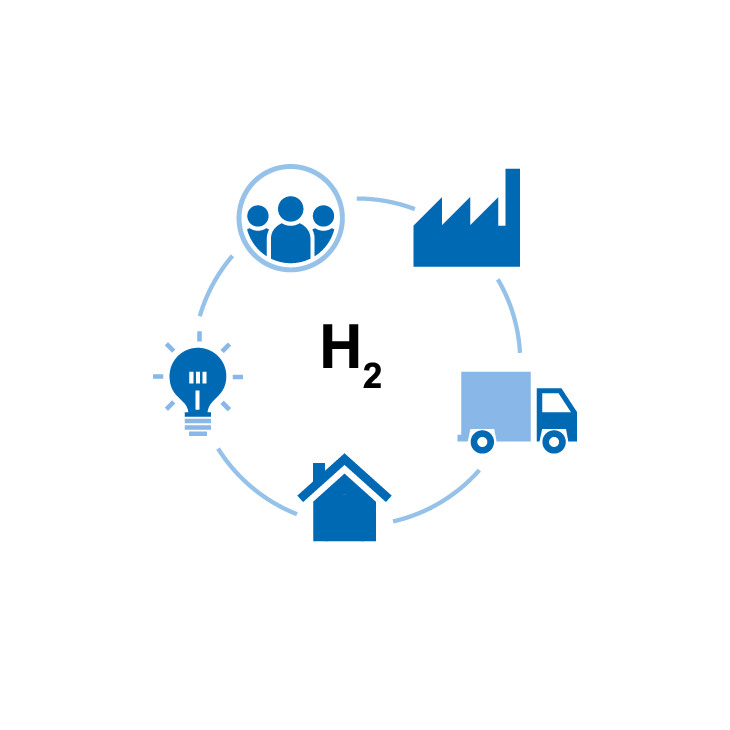

HyInnoSys

Market preparation, Hydrogen Ecosystem,

technology and knowledge transfer

Approach

- Develop viable business models and identify market introduction processes

- Analysis of the actors in the ecosystem, user acceptance of hydrogen technology

- Regulatory design of hydrogen-centred energy markets

- Techno-economic system analysis

- Derivation of future scenarios and implications for the coordination and development of hydrogen ecosystems